(Electrical/Component Issues)

See FAQ about Short Cycling boilers

START HERE

Are there any error codes displayed? Click yes and return you to “Main Menu” then select the proper soft or hard error code.

While the boiler is running in heat demand, press the status button. Wait until the boiler cycles off. Is the supply temperature at/near the setpoint temperature?

When the boiler is running, on the “Status” or Home screen is the water temperature rising very quickly? It is best to have a few seconds minimum between the degrees of temperature change. Is the water temperature rising quickly or is there a few second pause between the degrees of change.

On the same status screen, when the boiler shuts down is there a flashing triangle to the right of “Rate”.

Press the flashing triangle and read the rate limiter message. Click the message below.

Compare the temperature reading on display to the temperature/pressure gage on the supply pipe. Are the readings close?

Replace the supply sensor.

Was a heat loss done before the boiler was installed?

Do a heat loss manual J calculation. Reduce the maximum RPM’s in the Central Heat display under “Manual Modulation” to match the heat loss.

Calculate the average runtime in minutes

Average Minutes = (hours * 60)/Cycles

Adding a Sage Zone Control can assist in reducing the btu input of the boiler per zone size. The Sage Zone Control will actually communicate to the Sage2 boilers control and hold the boiler in a lower input to match the zone size.

Is the zone in demand much smaller than the minimum input of the boiler? Turn up more thermostats. Did the problem temporarily resolve?

Go to SZC Troubleshooting for programing directions

Reduce the Maximum RPM’s in the “Modulation Setup” Central heat menu by a minimum of 600 rpm’s. May need to repeat by smaller amounts until the temperature stops climbing but does not go down while in high fire.

Is there a strainer on the return side of the system piping or on the return side of the boiler piping. If there is a Webstone piping kit installed many of they have strainers built into the returns side of the kit. Is there a strainer installed somewhere in the piping?

Try these parameter changes, check pump speeds. If problem persists add a buffer tank

Press the status button on the display, Press the right arrow key and view the supply and return temperatures. Is the Delta-T greater or less than 35f?

Check circulator size and speed

Check pipe sizing

Check water flow

Turn on all the heat zones. After the boiler fires and releases from “Low Fire Hold” if available. Does the water temperature rise quickly or slowly?

Reduce the Maximum RPM’s in the “Modulation Setup” Central heat menu by 200 rpm’s. May need to repeat until the temperature stops climbing but does not go down while in high fire. Turn back up 100 rpm’s

Every indirect has a minimum btu input, this is determined by the tank manufacturer. When we know the minimum btu input the tank manufacturer utilizes the DOE Output from the boiler. Is the minimum BTU input for your indirect smaller than the DOE output of the boiler?

After doing the calculation is the Average run time minutes less than 10 or greater than 10 minutes? The higher the better. >20 Minutes is a good run time.

Touch the “Adjust” bottom twice. Next touch “login” than touch the zeros in the middle of the screen. Type “86” and the return button (bent arrow). Touch “Save” and “Adjust”. Next touch “Modulation Setup” the upper right of the 6 boxes on the screen. Scroll right with the right arrow key to DHW Maximum modulation. Reduce the RPM’s and press the check mark which will display the btu input. Do this until the btu input is equal to or better yet 10% less than the IWH tank manufacturer requirement.

A manual J heat loss has been a way of determining the size of a heating appliance for many years. The contractor will measure the home external walls and determine the direction the wall faces. He will also measure the size and construction of all windows and doors. He will also have to determine the amount of insulation in wall ceiling and floors. He will than use all this information into a computer program to determine the heat loss of the home. He can do the entire home as one package for a replacement boiler or room by room to know how much radiation needs to be in each room. Any other way of sizing the replacement boiler will cause the replacement boiler to be too large almost all the time. Many of these oversized boiler are usually 100% or more oversized.

Check parameter settings.

Sign onto the control using the password 86.

“DHW” menu

- set “Setpoint Temp” to 170f

- “Diff Above” to 10f

- “Reponses Speed” to 1

“Central Heat” menu

- Setpoint to 180f

- “Dif Above” to 10f

- “Low Fire Hold” set to 180 Seconds

“Modulation Setup” Menu

- “Light off Rate” to 3500 rpm’s

- If there are Micro-zones try reducing the amount of micro-zones by doubling up some zones

- Add a buffer tank

- Do a heat loss and replace boiler with proper sized boiler.

Display may vary by Version #

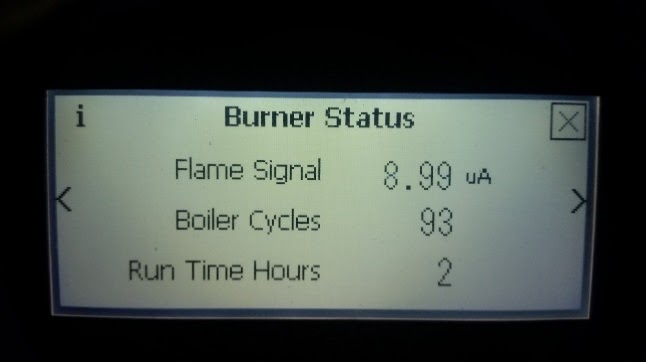

Cycles: 93

Hours: 2

Formula: (Hours x 60) / Cycles

Average run time in minutes: 1.3

FAQ: Short Cycling boilers

What is short cycling?

Boiler short cycling is when the boiler cycles on and off on high limit or setpoint temperature multiple times during a demand for heat or hot water. The idea with modulating condensing boilers is to run long run times with minimal gas input. This will allow the boiler to operate at a higher efficiency. The longer the cycle without affecting comfort the better the operation.

Why do boilers short cycle?

Boilers short cycle due to making more heat than the system can dissipate. See reason below.

- Micro-zones – The heat zones in demand require less btu’s than the minimum input of the boiler

- The water temperature is raising too fast to allow proper modulation

- Modulation too high or setpoint temperature too high

How do I know if the boiler is short cycling?

Many people in the heating industry have different ideas what a short cycle is. A very minimum cycle should be at least 10 minutes but 20 minutes or more is better. The longer the better due to the fan modulated lower which is a higher efficiency and reduces standby losses.

How do I calculate my cycle time?

- Use the display on the boiler.

- Press the “Status” button.

- Press the right arrow 3 times

- You should see “Boiler cycles” and” Run Time Hours” and depending on the version of the display possible more information

- Convert the hour to minutes and divide by the number of cycles

Formula is Average run time = (hours*60)/cycles

Please contact Technical Support for Access Parameters and/or to resolve this issue.